Hygra

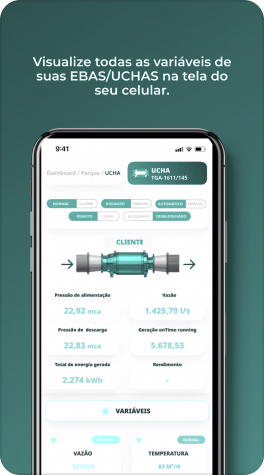

We know that failures can happen, but it is also important to know that before that, they will emit some signal. The monitoring system provides real-time control of pumps and turbo generators, with integrated alerts through IoT and assertive predictions to know the right time for parts replacement and maintenance.

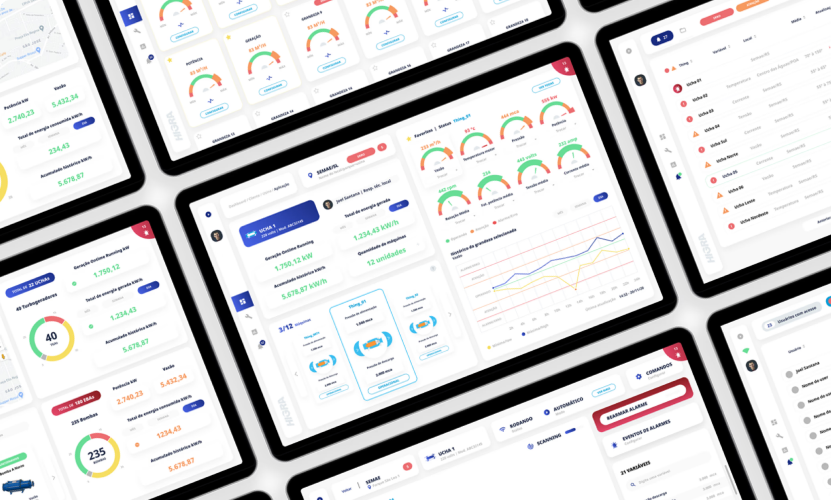

And, of course, control your machines, automate processes and manage activities on a single platform.

Challenge

Create a system that makes it possible to remotely monitor the conditions and operating regime of pumps based on data generated by existing sensors and make advance predictions about parts replacement.

The company's equipment is complex, and the current sensors on the machines collected a lot of data that was not analyzed correctly due to the large amount and lack of filtering. In addition, communication of errors and failures was impaired and there was no way to take quick action to resolve demands without causing losses.

Solution

The system we created using the AWS cloud, which guarantees high availability and scalability, allows an operational control center to receive automatic and real-time information from pumps and turbo generators.

This project, using IoT technology, monitors and collects data through sensors attached to pumps and turbo generators that monitor their useful life and alert about potential problems, with assertive analysis on the monitoring of water sanitation from the main suppliers in Brazil.

Furthermore, the most modern technologies on the market were used, ensuring safety, adaptability and reliability.

Every part of the project is designed for your business

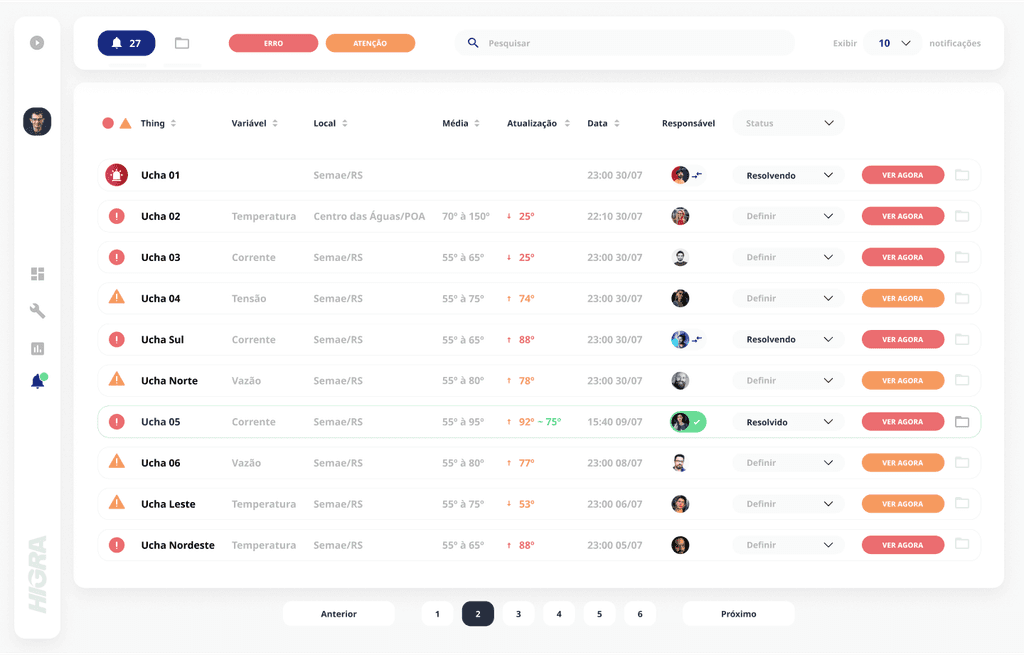

Notification system

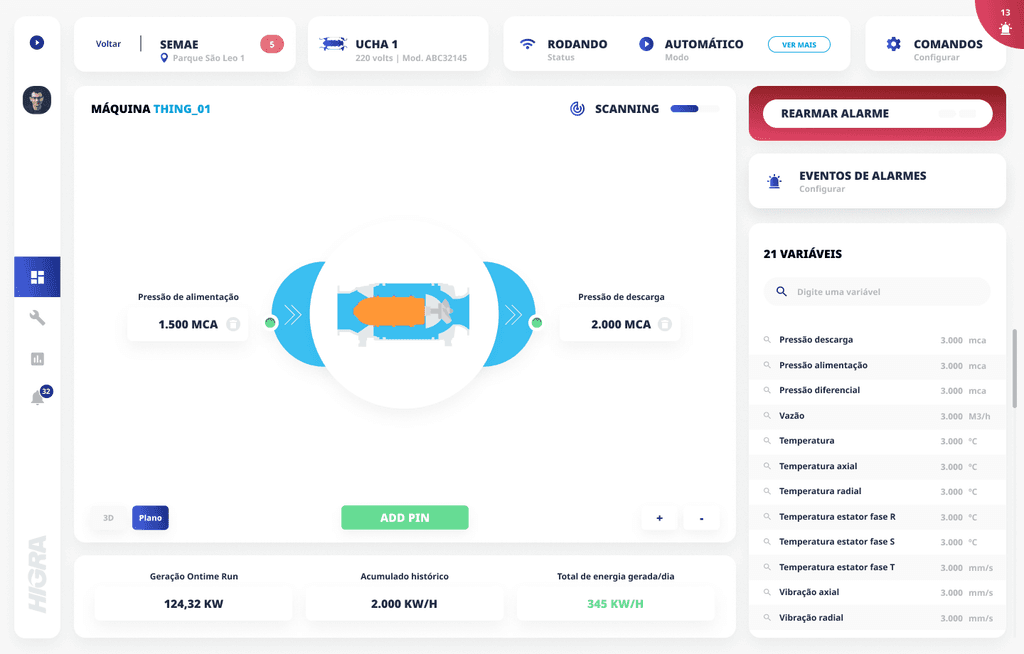

Remote control over equipment (from the web)

Notifications of failures, anomalies, maintenance alerts

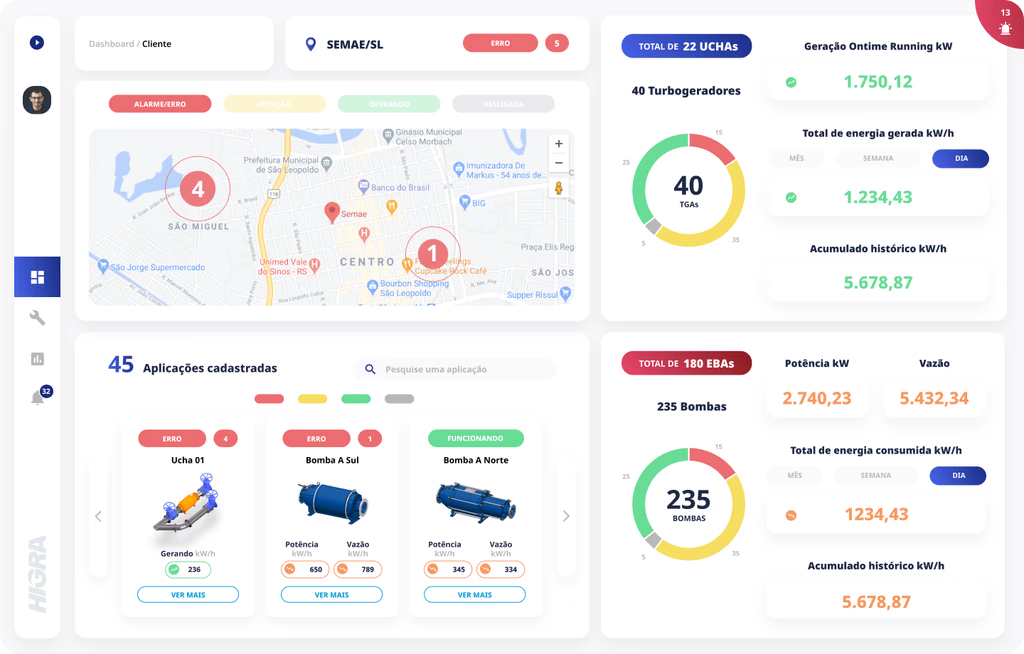

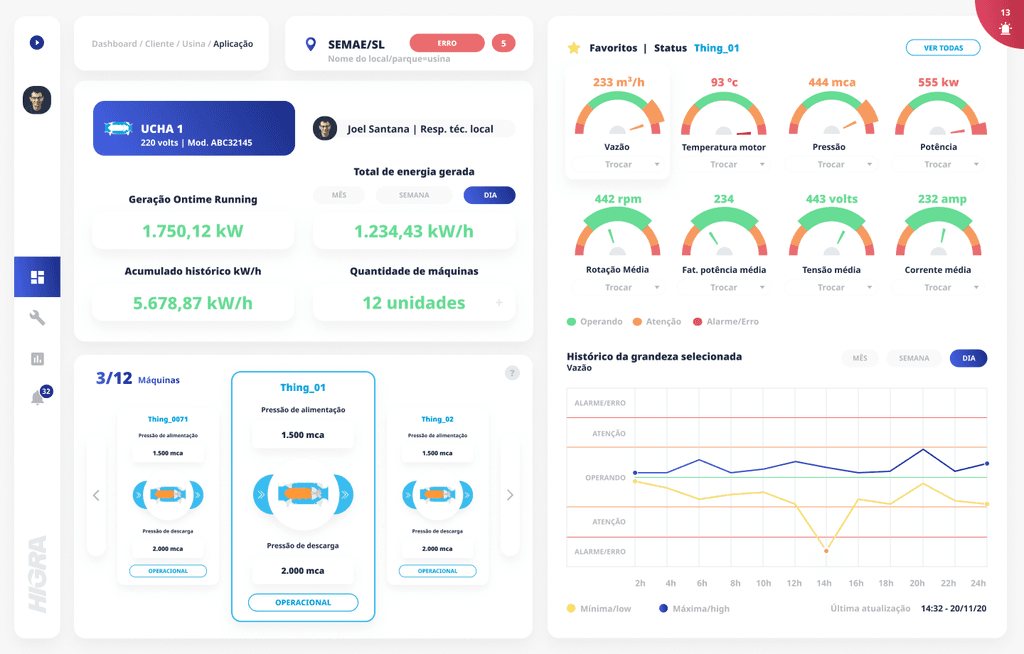

Customized dashboards with real-time information

History of parameters collected by sensors

Support ticketing system

Support, product and service reports

Transforming data into operational indicators

Monitoring the useful life of equipment

Discover the benefits of our project for your business

Data Control and Storage

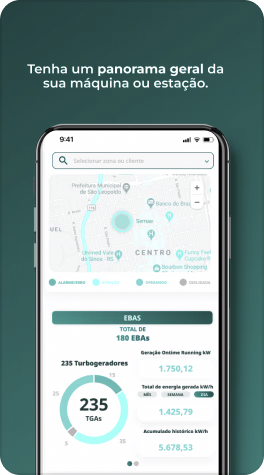

The system offers precise, real-time control of pumps and turbogenerators, enabling a 360º view of equipment operating conditions. We can use S3 (Simple Storage Service) for data storage, which is scalable and durable, enabling multiple database backups and configuration files.

Assertive and Agile Monitoring

It allows you to know exactly when a failure occurs in order to replace parts based on the data generated by the sensors, preventing failures from causing greater problems and enabling quick actions to speed up maintenance before supply runs out.

In-depth Data Analysis

With AWS IoT connecting devices to the cloud, it is possible to collect, store and monitor data, accelerating decision-making for equipment maintenance, all with remote control of IoTs.

Real-Time Mapping

The system offers real-time mapping of registered plants and stations, providing detailed information on each piece of equipment and its location, facilitating the management and monitoring of operations.

Versatile Platform

The solution is made up of IoT devices, mobile and web applications, enabling coupling to different devices and allowing monitoring even of devices in difficult-to-access environments, such as dessert pumps for water sanitation.

See what extra features are available with AWS

Lambda

AWS Serverless service that lets you run code in response to events.

CloudWatch

AWS monitoring and observability, allowing you to collect and track metrics, logs, and events for AWS resources and applications running in the cloud.

DynamoDB

It is a fully managed NoSQL database service by AWS with scalability and fast performance.

Amazon RDS

AWS relational database management with high availability.

Security Hub

AWS Security and Compliance that centralizes the collection, organization, and analysis of security alerts from multiple sources, such as AWS GuardDuty, Amazon Inspector, AWS IAM Access Analyzer, and more.

1 million

MWh of energy saved

41.5

Ktons less CO² emissions

7.5

Millions of kWh of clean energy generated

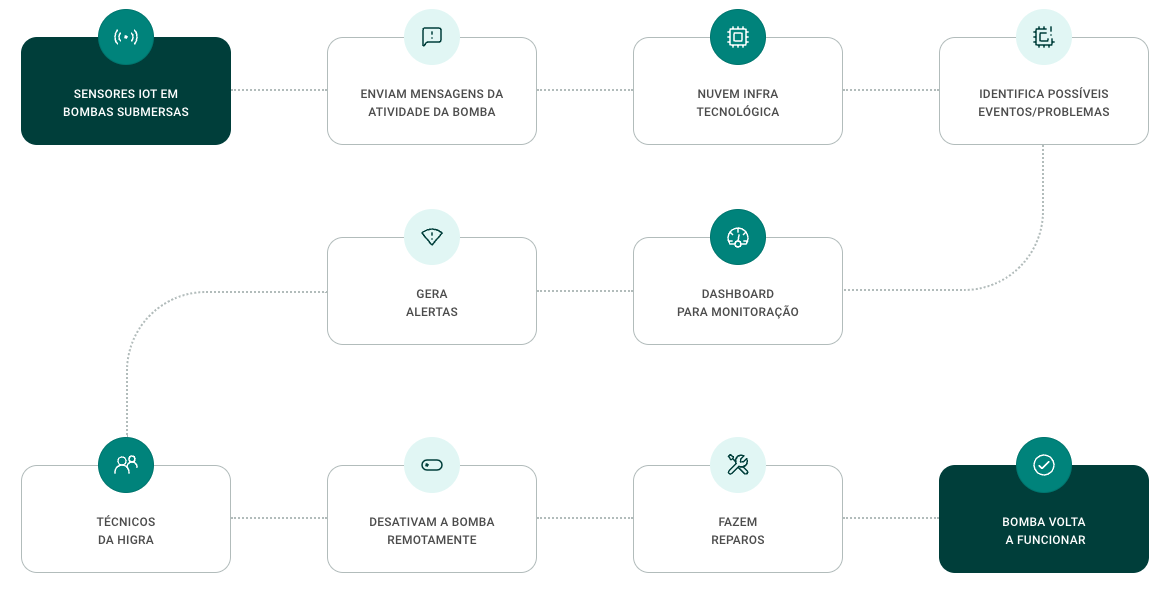

Understand how our solution works

Results

Enabled monitoring equipment to operate underwater

Reduction in maintenance time for equipment that has signaled failures

Avoids loss of equipment maintenance time

Avoids unnecessary stops in the water supply

Enabled greater control of pumps and turbo generators in real time

Reduced costs with faster repairs

Identifying opportunities for improvement

Increased reliability and safety in the operation of machines and systems